Product imtroduction

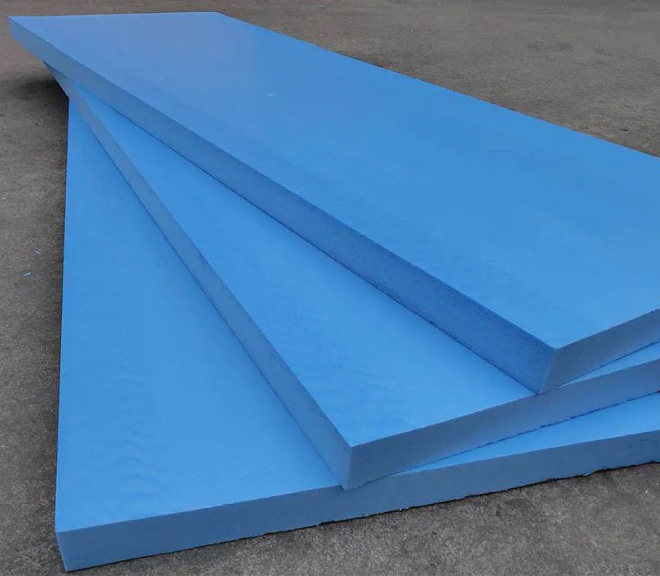

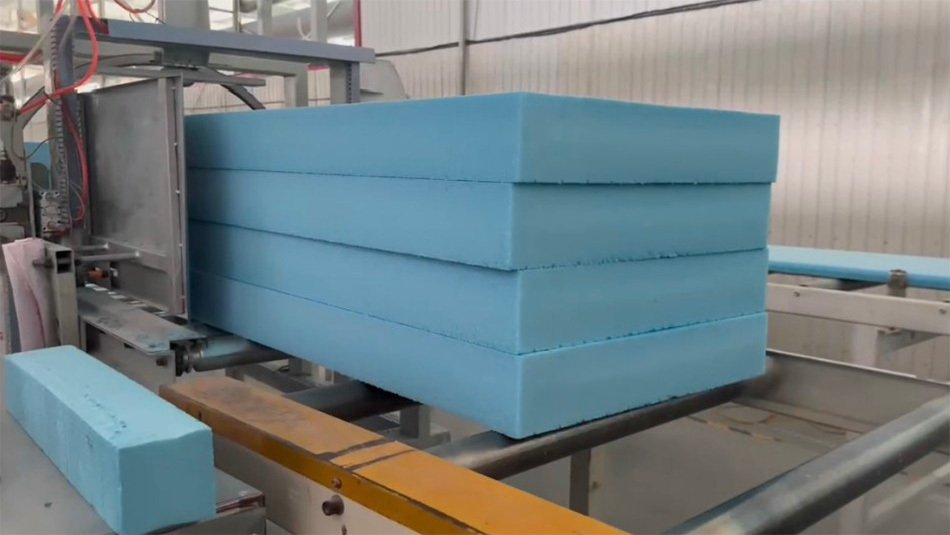

Extruded board, also known as extruded poystyrene board, xps board,is a kind of heated extrusion molding hard foam sheet is made of polystyrene resin and other aditives produced by extrusion process with continuous uniform surface and closed-hole honeycomb structure plate,is the third generation of hard foam insulation material, is a kind of construction insulation materials.

Product specification and size

Length | Width | Thickness | Density |

2400mm | 600mm | 20-150mm | 25-30/m³ |

To sum up, as an eficient, beautful healthy and envronmentaly fiendly heating method, the floor heating board is playing an increasingly important role in modern buildinos, By understandino its advanteges and characterstics, we can better choose and use the floor heating plate sytem, to provide strono suoport fo creating a more comfortable and healthy indoor environment.

Product technical indicators

Density | Kg/m³ | 32~45 |

Thermal conductivity,90 days,10℃ | W/mK | 0.028~0.03 |

Compressive strength at 10%deflection or | Kpa | 250~500 |

Water absorption | Vol-% | <=1.00% |

Capillarity | nil | nil |

Coefficient of linear thermal expansion | Mm/mK | 0.07 |

Temperature limits | ℃ | -50℃,+75℃ |

Performance characteristics

(1). Excellent thermal insulation insulation with the characteristics of high thermal resistance, low linearty and low expansion ratio, the closure rate of its structure reaches more than 99%, forming a vacuum layer, avoiding air fiow and heat disipaion, and ensuring the durabity and stabity of its insulation performance. Compared with the 80% dlosed hole rate of foaming polyurethane, the leading advantage is self-evident. practice has proved that the 20mm thick Xps extruded insulaton board is eauwalent to 50mm thick foam poystyrene and 120mm thick cement perite., Therefore, this material is curently the best choice for building insulation.

(2). Excelent high-strenoth compression resistance Due to the specialstucure of xps board its compresive strenoth and strong imgac resjistance, Accordinc to the diferent models and thickness ofxps,its compressive strength reaches more than 150 ~ 500 Kpa, which can withstand the ground load of each system, and is widely used in geothermal engineering,expressway, airport runway,square ground, large cold storage and interior decration insulation and other fields.

3). High qualtly of water hate, moisture-0rof Water absoroton rate is an imoortant parameter to measure themal insulation materals. The insulatior oerormance of the inswlation materal. decreases ater water absortion.in the case of low temoerature, the ihaled wateris easvto freze, destrovin the strucue of the insulation material

(4). Light in texture, easy to use The complete closed-hole foaming chemical structure of Xps plate and its honeycomb physical stnucture make it ight, high strength, easy to cut and transport, and not easy to break and easy to install.

(5). Good stabiity and anticorrosion resistance Long time, not aging, decomposion, does not produce hamfulsubstances, its chemical properties is extremely stable.

Performance characteristics

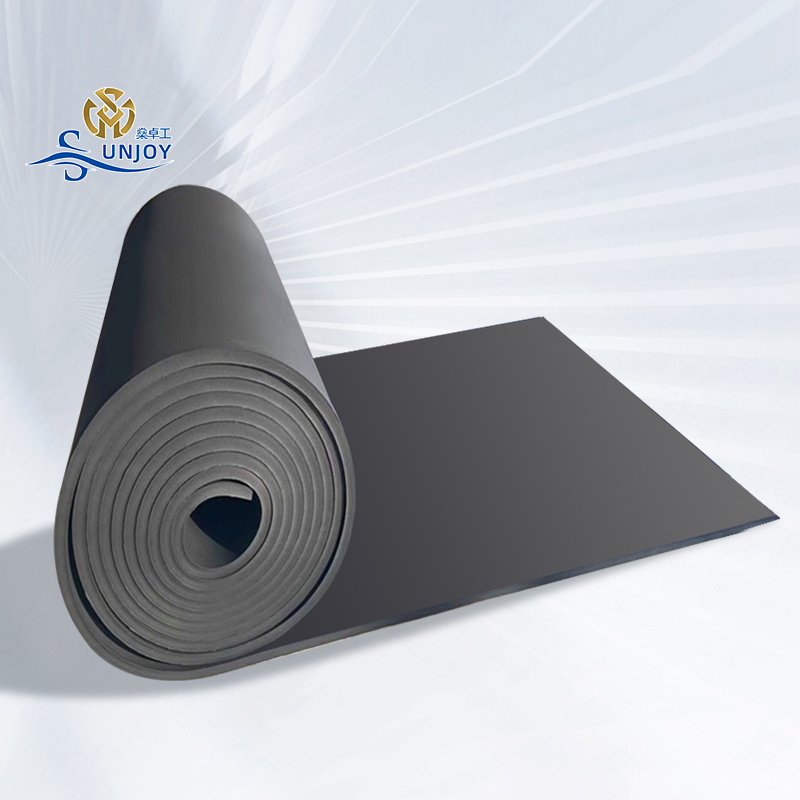

Extrusion plate funcion use is extrusion board thermal insulation moisiture efect, extrusion glate is widely ued, widel used, extusion board is mainy used in building wallroof insulation, stel structure roof, builing wall insulation, building ground moisturizing, square ground, ground frost control, central air conditioning ventilation pipe, airport runway insulation layer, high-speed railway subgrade and so on.

Keywords

XPS extruded polystyrene board

Contact Us

Classification

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!