Product Introduction

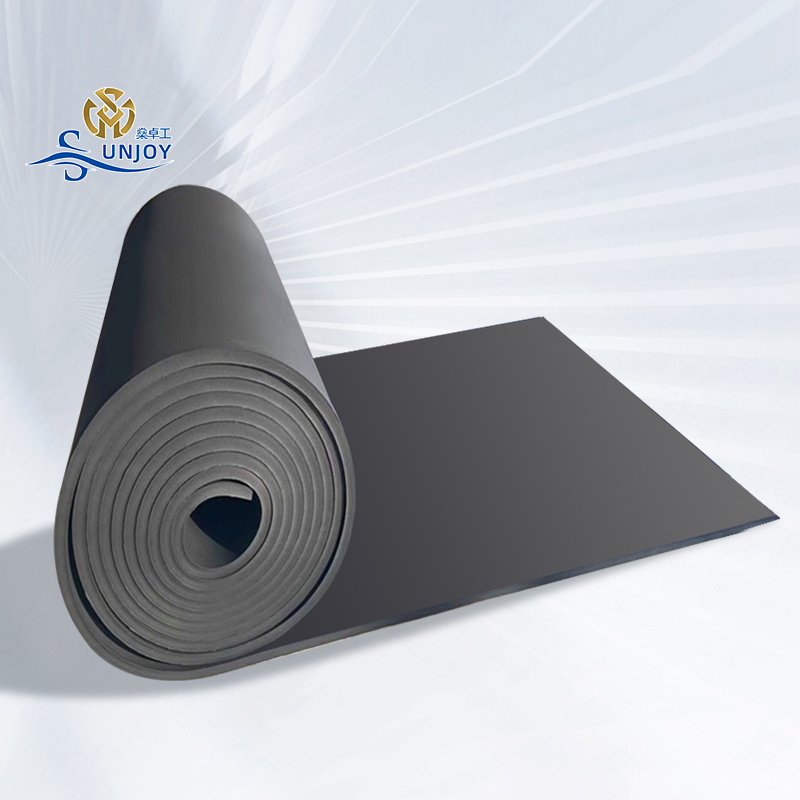

Plastic rubber is the abbreviation of rubber and plastic. It combines the dual characteristics of rubber and plastic, possessing the elasticity of rubber and the toughness of plastic. Plastic rubber materials are mainly composed of high molecular compounds. These compounds are processed through procedures such as mixing, extrusion, molding, and vulcanization to produce various rubber and plastic products with elasticity, insulation, water impermeability, and resistance to wear. There are various types of plastic rubber materials, including natural rubber, synthetic rubber, and various plastics. Natural rubber mainly comes from the latex of rubber trees and has excellent elasticity and wear resistance; synthetic rubber is produced through chemical synthesis methods and its properties can be adjusted as needed; plastics are a widely used synthetic material with diverse properties and can be widely applied in various fields.

The features and advantages of the product

The reason why rubber and plastic products can be widely used in various fields lies in their unique characteristics and advantages.

1. Thermal insulation performance

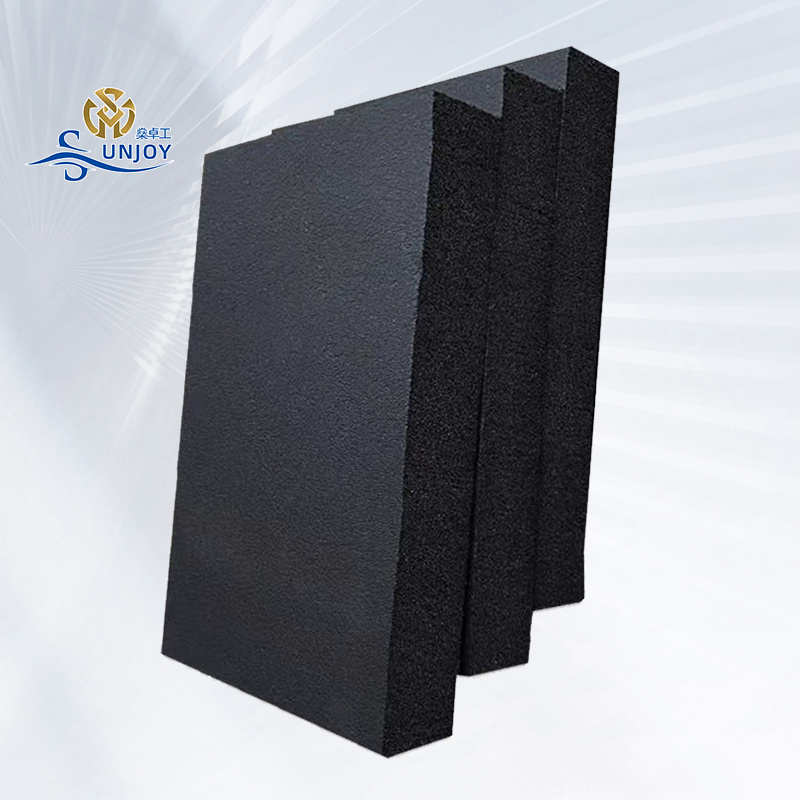

Rubber and plastic products have excellent thermal insulation performance, which can effectively reduce heat transfer and loss, thereby improving energy efficiency.

2. Noise reduction performance

Rubber materials have good sound insulation and noise reduction performance, which can effectively reduce noise pollution and improve living and working environments.

3. UV resistance performance

Rubber products have outstanding UV resistance performance, which can maintain stable performance under direct sunlight and extend service life.

In addition, rubber and plastic products also have excellent corrosion resistance, anti-aging performance, and environmental protection performance, making them widely used in many fields.

product use

Rubber and plastic are widely used in many fields because of their excellent physical and chemical properties.

1. Automotive industry: Plastics and rubber play a crucial role in the automotive industry. Whether it is the tires, seals, or various shock absorption and sound insulation components of the car, they all cannot do without rubber materials. For instance, rubber tires provide excellent grip and buffering effect, enhancing the safety and comfort of driving.

2. Construction industry: Plastics and rubber are mainly used in the construction industry for pipe insulation, waterproofing, and sound insulation. Rubber insulation materials have excellent insulation performance and weather resistance, effectively preventing the generation of cold and hot bridges in pipes and improving the energy efficiency of buildings. At the same time, rubber waterproof materials are also widely used in roof and basement waterproofing treatments.

3. Electronic and electrical industry: Plastics and rubber also play an important role in the electronic and electrical field. For example, rubber sealing rings and plastic insulating materials can effectively prevent leakage and short circuits during the assembly and use of electrical products.

4. Daily household items: Plastics and rubber are also widely used in daily life, such as rubber shoes, rubber gloves, plastic containers, plastic bags, etc. These products are not only convenient and practical, but also affordable, and are highly favored by consumers.

PREVIOUS:

NEXT:

Keywords

Plastic and rubber insulation board

Contact Us

Classification

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!