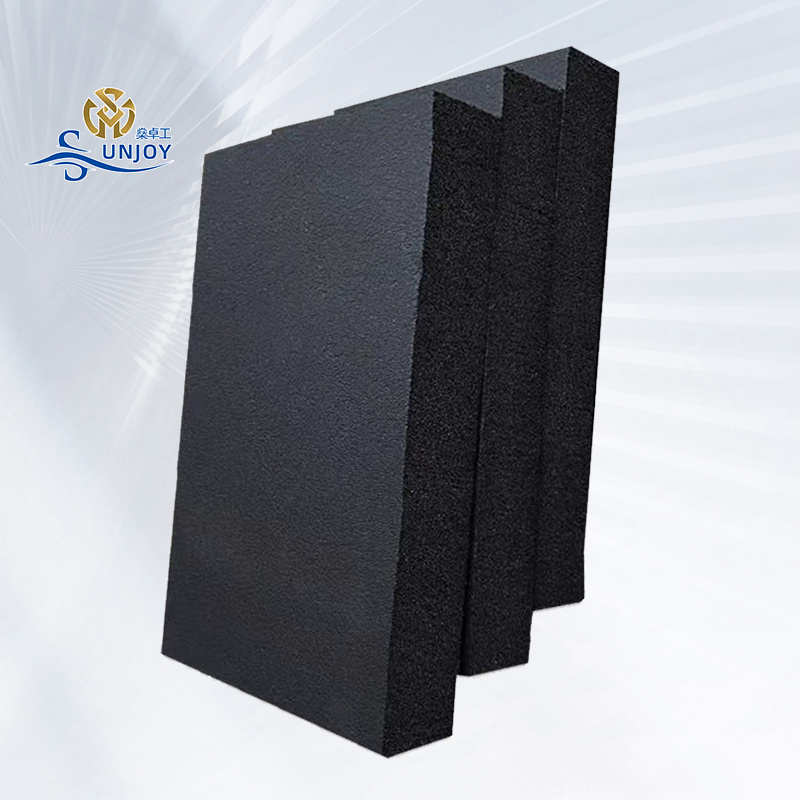

Product Introduction

Rock wool strips are made from natural basalt as the main raw material. After being melted at high temperature, they are processed into artificial inorganic fibers by a high-speed centrifugal equipment. Special adhesives and dust-proof oil are added at the same time, and then they are heated and solidified. Then, according to different requirements of users, they are cut into rock wool strips. Rock wool strips are made by cutting high-strength rock wool boards into specific structures, so they have high compressive strength and excellent fire resistance. Rock wool strips serve as the filling material for rock wool sandwich panels, providing excellent fire resistance for wall panels and roof panels. Various specifications of products produced using chemical quick-drying adhesives and mechanical curing technology have made significant contributions to creating a stable, insulated, soundproof, safe, and high-quality exterior wall.

Product features

Sound absorption/sound insulation: The open structure of the rock wool strips provides excellent sound absorption and sound insulation performance.

Fire resistance: This product has been tested according to the ASTM E-136 standard and is classified as a non-combustible product.

Tensile strength: The rock wool strips are made from profiled sheets and the fibers are in an upright position during the production process on the assembly line. Therefore, they can withstand high loads: 5%: with a tensile pressure greater than 25Kpa; 10%: with a tensile pressure greater than 40Kpa.

Water resistance: The rock wool strips are waterproof and have a good ability to release water vapor pressure to the roof structure.

PREVIOUS:

NEXT:

Keywords

Rock wool strips

Contact Us

Classification

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!