Product Details

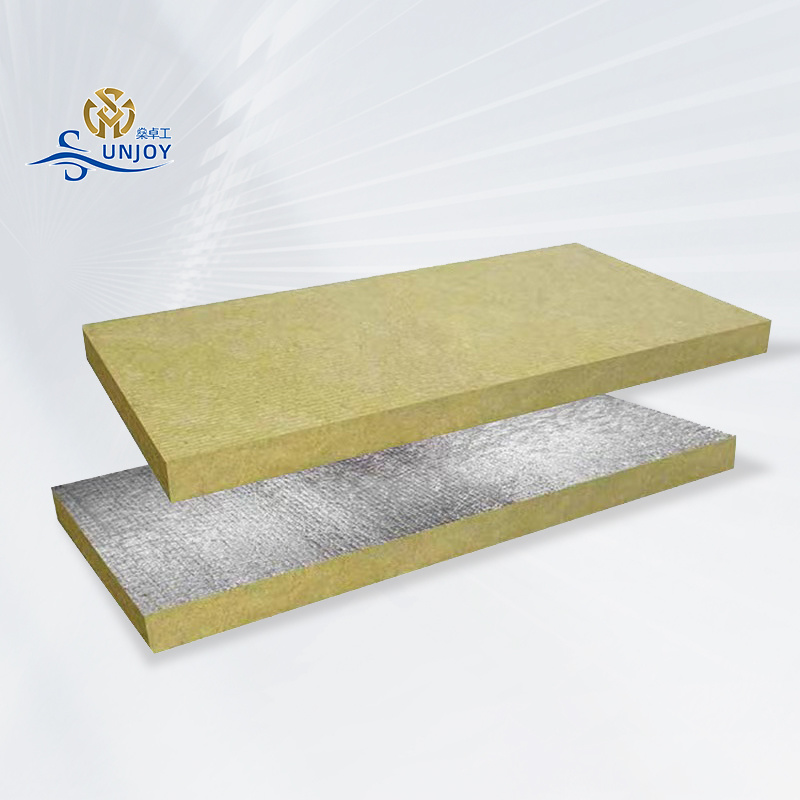

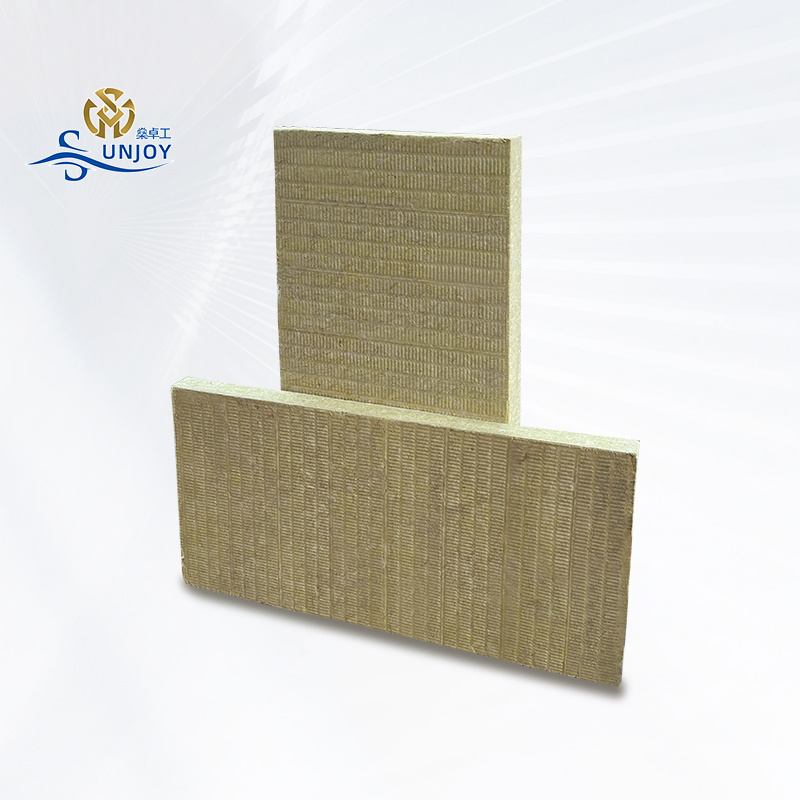

Glass wool slab is a plate-like material formed by adding phenolic resin adhesive to glass wool felt and then heating and curing. It can be surface-coated with PVC film fabric or aluminum foil. This product has the characteristics of small capacity, high sound absorption coefficient, flame retardancy, and good chemical stability.

product Introduction

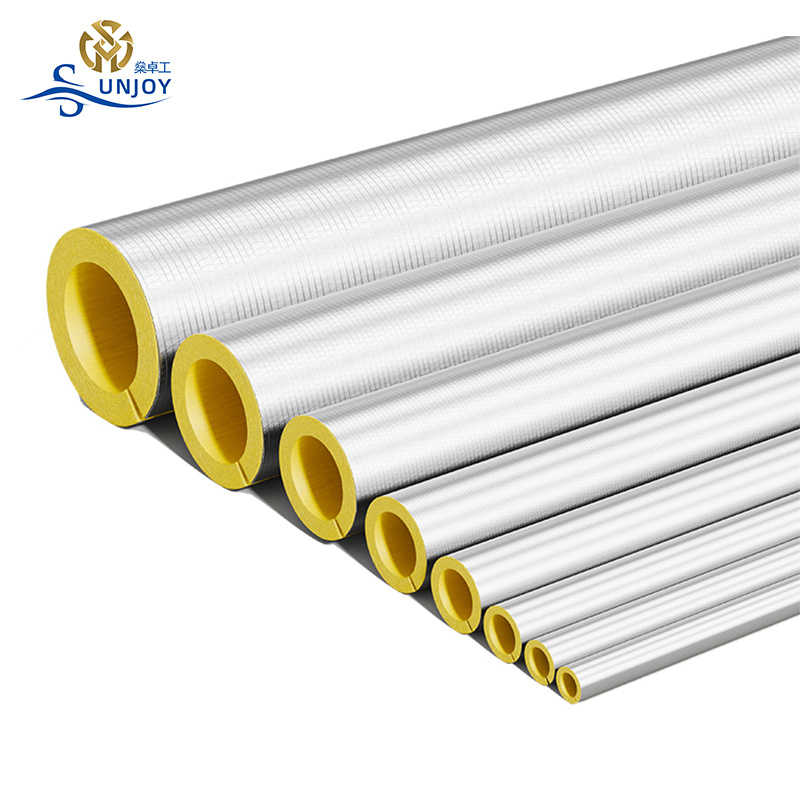

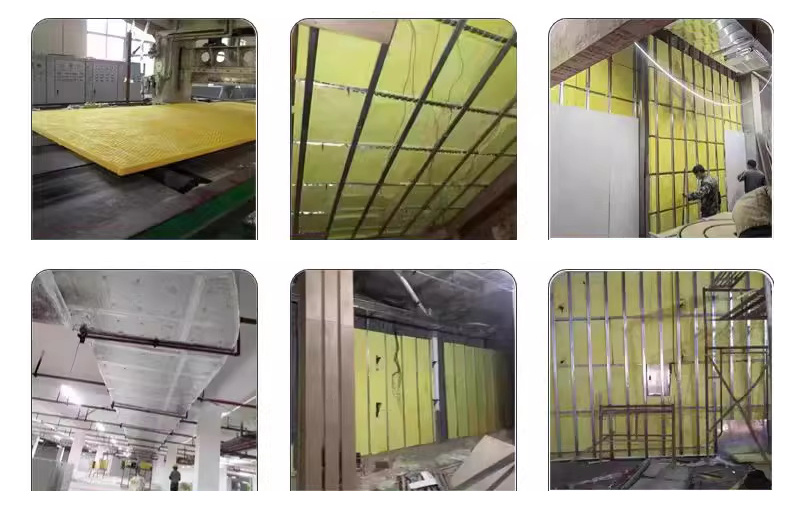

Glass wool slab is placed in the glass of meltdown appearance proceed the fiber turn and spray the resin of solid that draw the hot silk wadding form material, then turn through hot solid the deep processing handles and can also make into the series andvarious products. Glass wool slab is processed by putting the thermosetting binder into the glass wool, by pressing and heating, and then, by curing. They are widely used for insulation ,ventilation and the adjustment of air-conditioner incommercial industry and residential construction. Meanwhile, it has the effect ofenergy-saving insulation, sound controlling and improving the indoor air quality. glass wool slab is rigid but flexible product and no corrosion to the tank or pipe surfaceeasy to install and fixed with wire or banding and clip, then covered by galvanized sheet or aluminum sheet to protect the glass wool from UV, weathering influence.

Product Performance

·Low thermal conductivity

· Low temperature can be used

· Fire resistance, non-combustible A1

· Stable fiber structure

·Asbestos free, non-toxic

·Sound absorption, noise reduction

·Excellent stiffness and recovery characteristics

Product Specification

| IW-GS 24 | IW-GS 32 | IW-GS 48 | IW-GS 64 | IW-GS 98 | |

| THK (MM) | 30-150 | 40-140 | 30-100 | 20-80 | 10-50 |

| W (MM) | 600-1200 | 600-1200 | 600-1200 | 600-1200 | 600-1200 |

| L (MM) | 1200-1200 | 1200-1200 | 1200-1200 | 1200-1200 | 1200-1200 |

| FACING | Aluminum foil, kraft-paper, black tissue, or customized finish | ||||

| REMARK | other specification , pls contact our sales | ||||

Technical Data(ASTM C553)

| Item | Test Method | Standard Value | Test Value | |

| Service Temperature | ASTMC612-14 | No warping, flaming.glowing, Smolderingand smoking | 400°C | |

| Non-Fibrous (Shot) content(%) | ASTMC612-14 ASTM C1335-12 | ≤25 | 10.1% | |

| Thermal Conductivity W/(m·k) | 24°C | ASTM C612-14 ASTMC518-17 ASTM C177-19 | ≤0.036 | 0.036 |

| 93°C | ≤0.043 | 0.041 | ||

| 204°C | ≤0.061 | 0.056 | ||

| 260°C | ≤0.076 | 0.068 | ||

| 371°C | ≤0.108 | 0.085 | ||

| Compressive Resistance at 10% deformation | ASTM C612-14 ASTMC165-07(2017) | 22.4 | 32kpa | |

| Semi-rigid or Rigid | ASTMC612-14 | Semi-rigid or Rigid | Semi-rigid | |

| Flame Spread Index | ASTM C612-14 ASTME84-18 | ≤25 | 0 | |

| Smoke-developed Index | ASTM C612-14 ASTME84-18 | ≤ 50 | 0 | |

| Odor Emission | ASTM C612-14 ASTMC1101/C1101M-06 | A detectable odor of Objectionable nature recorded by morethan two of the five panel members shall constitute rejec | None of 5 members considered the odor was objectionable and strong. | |

| Water Vapor Sorption by weight | ASTM C612-14 ASTMC1104/C1104M-19 | S5.0% | 2.3% | |

| Corrosiveness to Steel | ASTM C612-14 ASTMC665-17 | ≥21 | 46 | |

| Resistance to Fungi | ASTM C612-14 ASTMC1338-14 | Growth no greater than that a comparative itemcomparative | No growth apparent under 40 times magnification | |

♦Waterproof

♦Non combustible in category A

♦In case of exposure to thermal and humidity, there will be no change in dimension.

♦It does not fall off in time, decay, get moldy, corrosion affected or oxidize.

♦It is not battered by bugs and microorganisms.

♦It is neither hygroscopic, nor capillary.

♦ Easily installed

♦ Made from up to 65% recycled content

♦ Reduces overall building energy usage

♦ Easily transported around site due to packaging

♦ Can be custom cut to required length to reduce waste and installation time

♦not fall off, decay in time, is neither hygroscopic, nor capillary.

♦No occurrence of corrosion or oxidization.

♦In case of exposure to thermal and humidity, there will be no change in dimension.

♦It does not fall off in time, decay, get moldy, corrosion affected or oxidize.

♦It is not battered by bugs and microorganisms.

♦It also acts as sound isolator as well as thermal isolator with its vibration conserving feature.

Behind radiators (decreases heat loss by heat transmission)

Thermal and sound insulation in sides

Interior thermal and sound insulation of wooden houses

Exterior insulation of HVAC pipes and rectangular or square cut ventilation pipes

On the walls of boiler rooms and generator rooms

Elevator engine rooms, stairs rooms

PREVIOUS:

Keywords

Glass wool board

CONTACT US

Classification

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!