Product Introduction

Density : 56 kg /m³ ~ 80 kg / m³

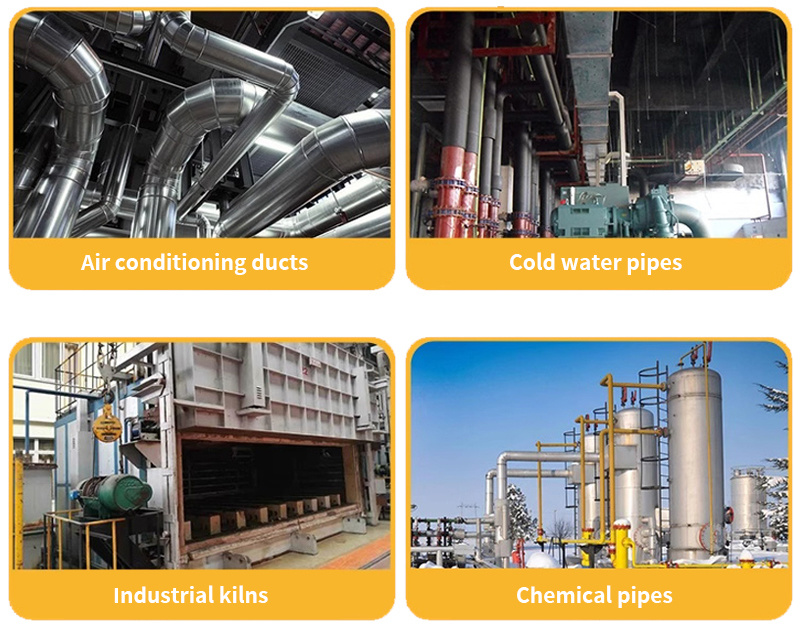

Excellent heat and cold insulation properties use

Insulation ( cold ): Insulation and cooling of steam, hot and cold water pipelines in various factories, ships, schools, hospitals, etc.

Residential silencing : drainage pipe silencing in residential areas, hospitals, schools, and residences.

Common specifications:

56㎏ /m³ Products

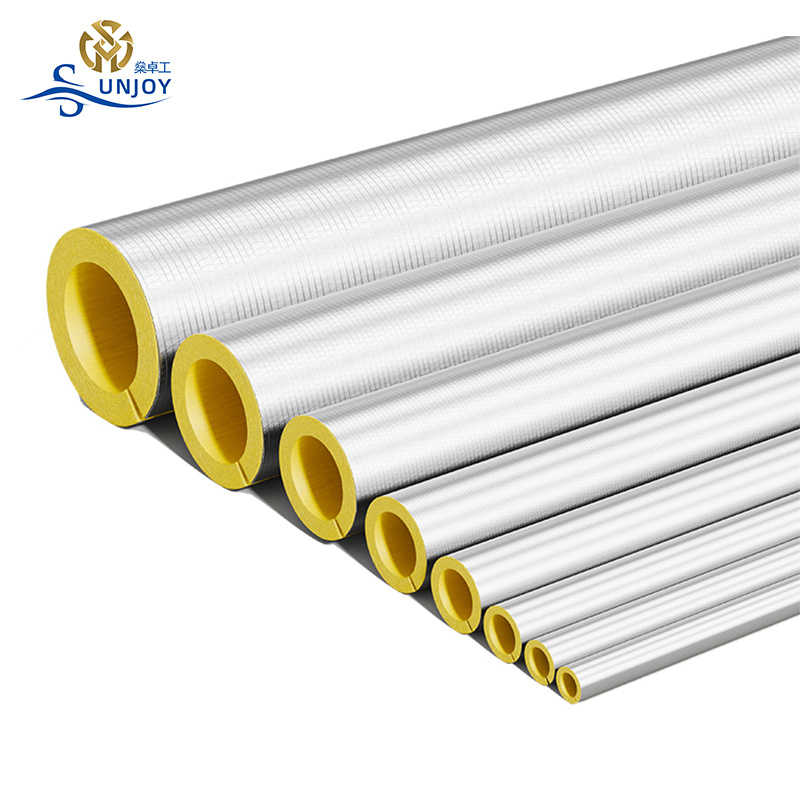

The insulation glass wool tube is made from natural rock as raw material, through high-temperature melting and centrifugal process, and is covered with a protective layer on the outside.

Product Introduction

Glass wool tube insulation is one-piece, 1000mm long hinged sections of fiberglass pipe Insulation that are opened, placed over the pipe and secured in place.lt is widely usedto insulate iron, copper, and other pipelines with operating temperatures between -120°C to 400°C in commercial & institutional buildings, and industrial facilities.

Product Performance

·Low thermal conductivity

·Low temperature can be used

·Fire resistance, non-combustible A1

·Stable fiber structure

·Asbestos free, non-toxic

·Sound absorption, noise reduction

·Excellent stiffness and recovery characteristics

Product Specification

| Type | GLASS WOOL PIPE 48,GLASS WOOL PIPE 64,GLASS WOOL PIPE 76 | |||||||||||

| Dia | Thickness (mm) | |||||||||||

| DN | INCH | ID | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 120 |

| 15 | 1/2 | 22 | ||||||||||

| 20 | 3/4 | 27 | ||||||||||

| 25 | 1 | 34 | ||||||||||

| 32 | 1-1/4 | 42 | ||||||||||

| 40 | 1-1/2 | 48 | ||||||||||

| 50 | 2 | 60 | ||||||||||

| 65 | 2-1/2 | 73 | ||||||||||

| 80 | 3 | 89 | ||||||||||

| 90 | 3-1/2 | 102 | ||||||||||

| 100 | 4 | 114 | ||||||||||

| 125 | 5 | 141 | ||||||||||

| 150 | 6 | 168 | ||||||||||

| 200 | 8 | 219 | ||||||||||

| 250 | 10 | 273 | ||||||||||

| 300 | 12 | 325 | ||||||||||

| 350 | 14 | 356 | ||||||||||

| 400 | 16 | 406 | ||||||||||

| 450 | 18 | 457 | ||||||||||

| 500 | 20 | 508 | ||||||||||

| 550 | 22 | 559 | ||||||||||

| 600 | 24 | 610 | ||||||||||

| Facing | Aluminum foil, PVC, black tissue, etc. or customized finish | |||||||||||

| Note | other size please contact our sales | |||||||||||

Technical Data

| ltem Name | Test Method | Standard Value | Test Value | |

| Dimension | ASTMC302-13(2017) | pass | ||

| Thermalconductivity W/(m·k) | 24°C | ASTMC335-17 ASTMC1045-19 | ≤0.036 | 0.035 |

| 93°C | ≤0.045 | 0.042 | ||

| 204°C | ≤0.065 | 0.063 | ||

| 260°C | ≤0.078 | 0.076 | ||

| 371°C | ≤0.111 | 0.101 | ||

| Service Temperature | ASTMC411-19 ASTMC417-15 | ≤400°C | 396°C | |

| Slag Resistance,max thickness change | ASTMC411-19 | ≤5.0% | 3.67% | |

| Non-Fibrous (Shot) content | ASTMC1335-12(2017) | ≤25% | 8.7% | |

| Linear Shrinkable at maximumuse temperature( 400°C) | ASTMC356-17 | ≤2.0% | 1.2% | |

| Water Vapor Sorption By Weight | ASTMC1104/C1104M-13a | ≤5.0% | 0.2% | |

| Flame Spread Index | ASTME84-19a | ≤25 | 0 | |

| Smoke-developed Index | ≤50 | 0 | ||

| Stress Corrosion Performance | ASTMC795-08(2013) | No crack | pass | |

PREVIOUS:

Keywords

Aluminum Foil Glass Insulation Cotton Tube

CONTACT US

Classification

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!