Product Overview

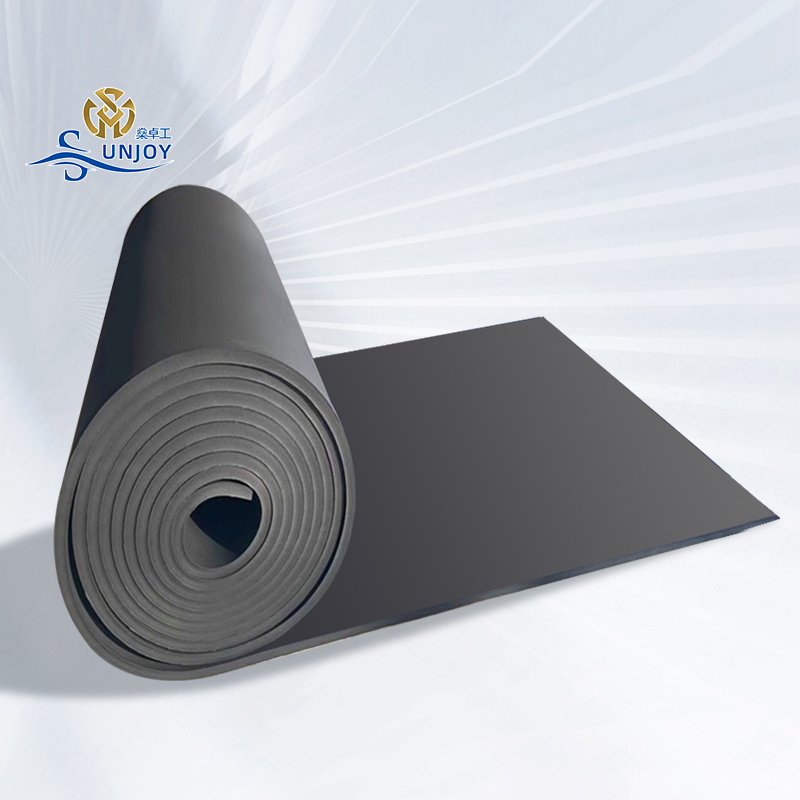

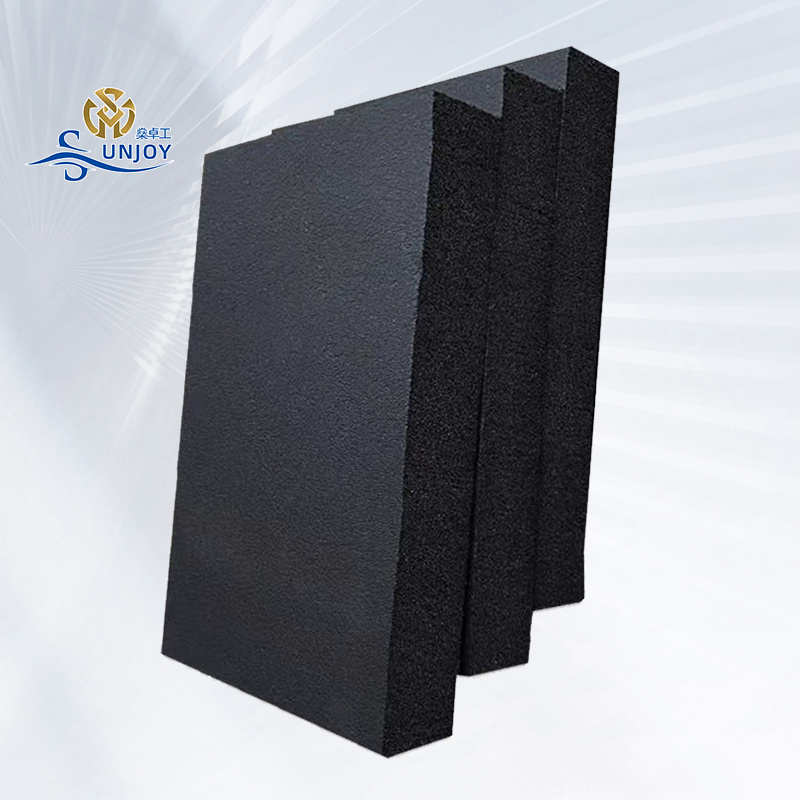

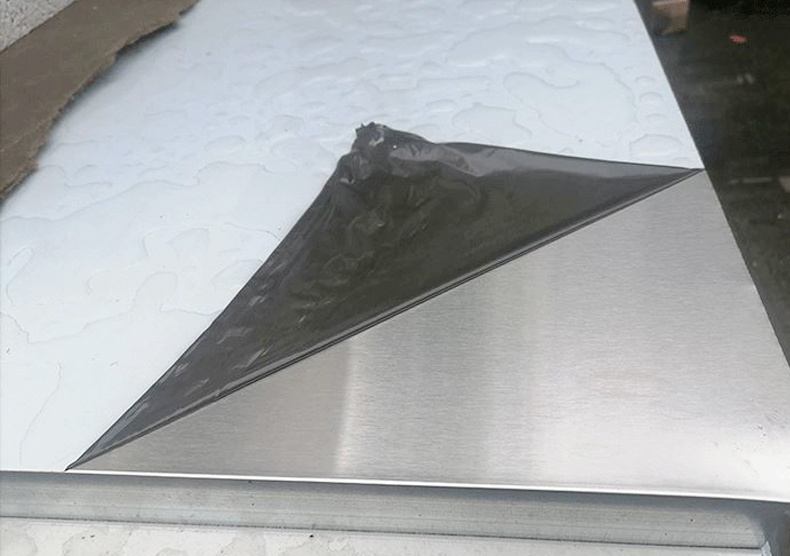

EPS (Expanded Polystyrene) sandwich panels are advanced building components crafted for diverse construction applications. These panels are composed of two outer layers, typically made from galvanized steel, aluminum, or other durable materials, with a core of expanded polystyrene foam. The outer layers offer strength and a finished appearance, while the EPS core provides insulation and contributes to the panel's overall performance. Manufactured in factory - controlled environments, EPS sandwich panels are available in a variety of sizes, thicknesses, and surface finishes, making them adaptable to different building requirements.

Product Features

Exceptional Thermal Insulation

The EPS core of these sandwich panels is renowned for its outstanding thermal insulation properties. EPS has a low thermal conductivity, which effectively impedes heat transfer. In residential buildings, this helps maintain a comfortable indoor temperature year - round, reducing the need for excessive heating or cooling. For commercial and industrial facilities, EPS sandwich panels can significantly cut down on energy consumption in large - scale spaces, leading to substantial cost savings in utility bills.

Lightweight yet Strong

EPS sandwich panels are lightweight, which simplifies handling and installation. Despite their low weight, the combination of the rigid outer layers and the EPS core provides remarkable strength. They can withstand normal building loads, including wind pressure and minor impacts. This makes them suitable for use in a wide range of construction projects, from single - story residential homes to multi - story commercial buildings, without compromising on structural integrity.

Cost - Effective

One of the major advantages of EPS sandwich panels is their cost - effectiveness. The manufacturing process of EPS foam is relatively inexpensive, and the panels are quick to install, reducing labor costs. Additionally, their excellent thermal insulation properties lead to long - term energy savings. These factors make EPS sandwich panels an attractive option for budget - conscious builders and property owners who still demand high - quality building materials.

Good Sound Absorption

The EPS core also contributes to sound absorption within the panels. They can effectively reduce airborne noise, creating a quieter indoor environment. This is particularly beneficial in residential areas near busy roads or in commercial spaces such as offices, schools, and hospitals where noise control is essential for a comfortable and productive atmosphere.

Moisture Resistance

While EPS foam is naturally hydrophobic, the outer layers of the sandwich panels are designed to provide additional protection against moisture. The metal or composite outer skins act as a barrier, preventing water penetration and ensuring that the insulation properties of the EPS core remain intact over time. This makes EPS sandwich panels suitable for use in both interior and exterior applications, even in areas with high humidity.

Easy Installation

EPS sandwich panels are designed for straightforward installation. Their pre - fabricated nature allows for quick assembly on - site. The panels can be easily cut to size using standard tools, and they can be joined together using various connection methods, such as self - tapping screws or specialized panel connectors. This ease of installation not only saves time but also reduces the complexity of construction projects.

Customizability

These panels offer a high degree of customizability. The outer layers can be finished in different colors, textures, and coatings to match the aesthetic requirements of any building design. Additionally, the thickness of the EPS core and the type of outer material can be selected based on specific performance needs, such as insulation requirements or load - bearing capacity.

PREVIOUS:

NEXT:

Keywords

EPS sandwich panels

Contact Us

Classification

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!