Product Overview

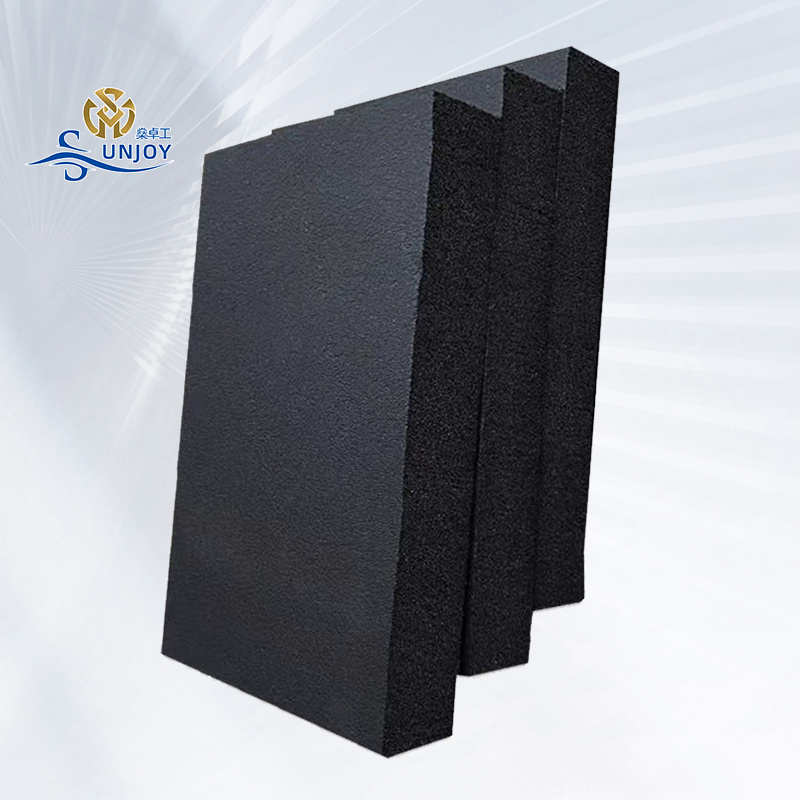

Rock wool sandwich panels are innovative building materials that consist of two outer layers, typically made of galvanized steel, aluminum, or other metal sheets, with a core of high - quality rock wool insulation material. The outer layers provide strength and durability, while the rock wool core offers excellent thermal, acoustic, and fire - resistant properties. These panels are pre - fabricated in a factory setting, ensuring consistent quality and precision in their dimensions. They come in various sizes, thicknesses, and finishes, making them suitable for a wide range of applications in the construction industry.

Product Features

Exceptional Thermal Insulation

The rock wool core in our sandwich panels is a highly efficient thermal insulator. It has a low thermal conductivity, which means it effectively reduces heat transfer between the interior and exterior of a building. This property helps to maintain a stable indoor temperature, whether it's keeping the warmth in during winter or the coolness in during summer. As a result, buildings constructed with rock wool sandwich panels can significantly reduce energy consumption for heating and cooling, leading to cost savings in the long run.

Superior Fire Resistance

Fire safety is a crucial aspect in building design, and our rock wool sandwich panels excel in this area. Rock wool is non - combustible and has a high melting point. In the event of a fire, the panels act as a reliable fire - resistant barrier, preventing the spread of flames and heat. They do not release toxic gases or smoke, providing valuable time for evacuation and minimizing property damage. This makes them an ideal choice for buildings where fire protection is a top priority, such as industrial facilities, high - rise buildings, and public buildings.

Excellent Sound Absorption

Noise pollution can be a major concern in both residential and commercial environments. Our rock wool sandwich panels are designed to address this issue. The porous structure of the rock wool core effectively absorbs sound waves, reducing both airborne and impact noise. In residential buildings, they can dampen the noise from traffic, neighbors, or household appliances. In commercial spaces like offices, schools, and hospitals, the panels create a quiet and comfortable environment conducive to work, study, and recovery.

High Strength - to - Weight Ratio

Despite their relatively lightweight nature, rock wool sandwich panels offer remarkable strength. The combination of the sturdy outer metal layers and the dense rock wool core results in a panel that can withstand significant mechanical stress. They are resistant to bending, impact, and wind loads, making them suitable for use in various building applications, including wall and roof cladding. This high strength - to - weight ratio not only simplifies the installation process but also reduces the overall structural load on the building, allowing for more cost - effective construction.

Durability and Long - Lasting Performance

Our rock wool sandwich panels are built to last. The outer metal layers are often coated with corrosion - resistant materials, protecting the panels from rust and environmental degradation. The rock wool core is also highly resistant to moisture, mildew, and biological growth. This ensures that the panels maintain their performance over an extended period, even in harsh environmental conditions. With minimal maintenance requirements, they offer long - term value for building owners.

PREVIOUS:

NEXT:

Keywords

Rock wool sandwich panels

Contact Us

Classification

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!