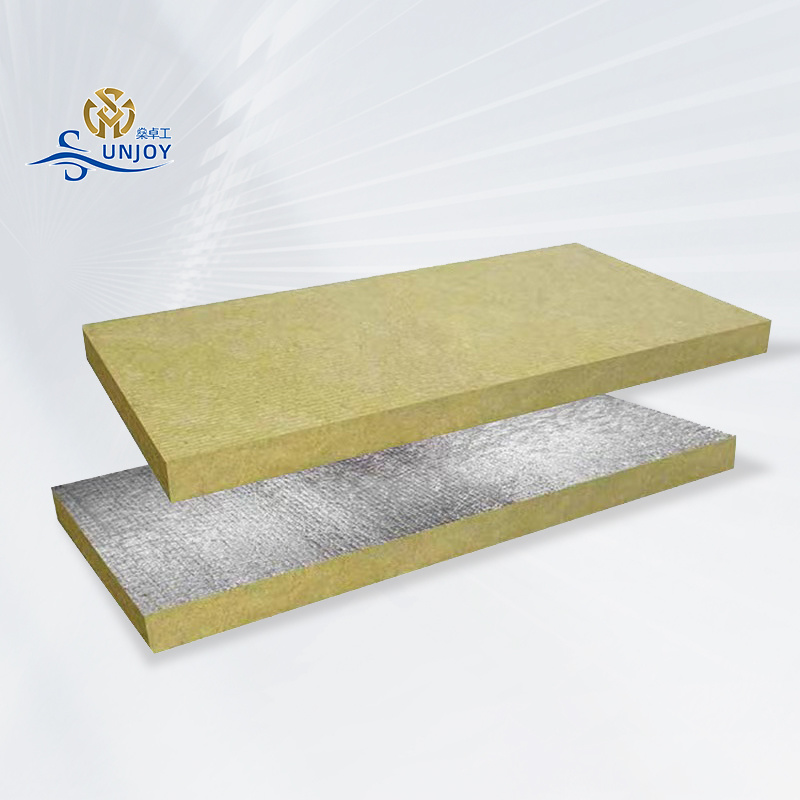

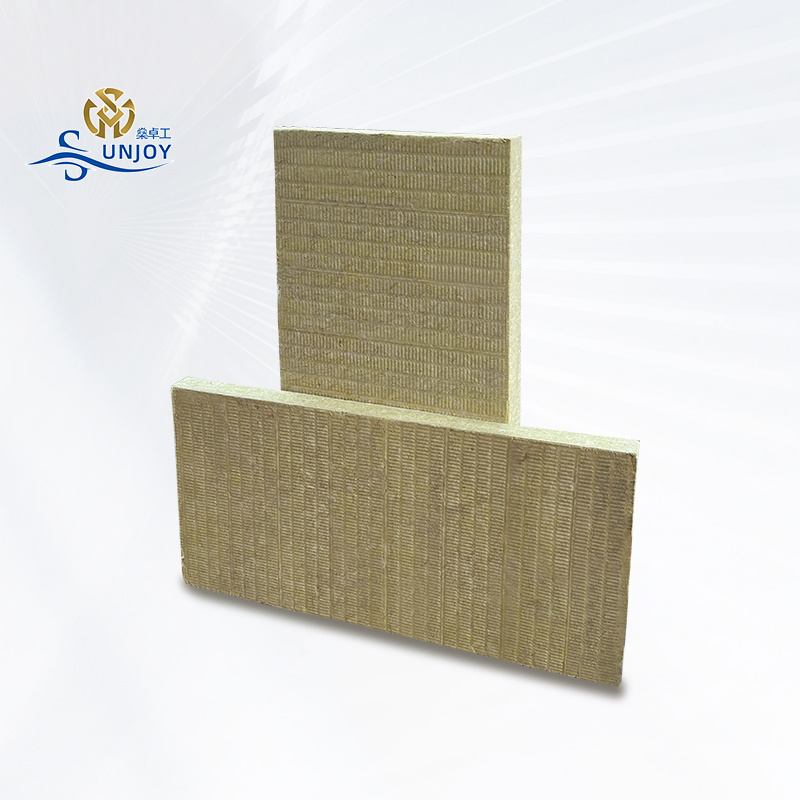

Product Details

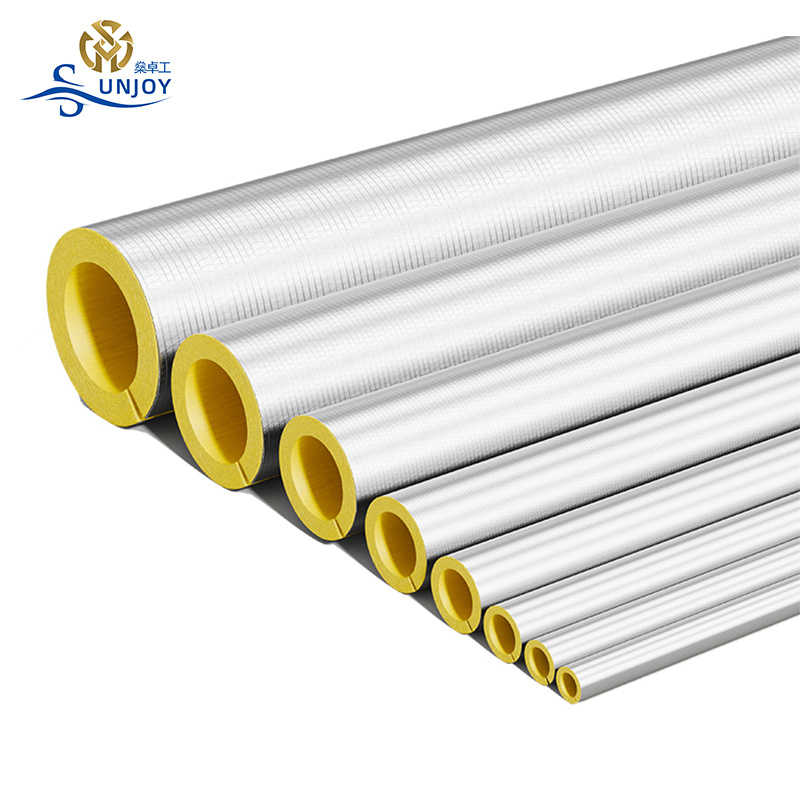

Rock wool pipe is a kind of rock wool insulation material mainly used in pipelines. Rock wool pipe shell is widely used in the insulation of boilers and equipment pipes in petroleum, chemical plants, metallurgical industry, ships, textile industry, etc. It is also used for the insulation of partition walls, ceilings and interior walls in the construction industry, as well as the insulation of various types of cold and hot pipes and hidden and exposed pipes.

Product Introduction

Rock Wool pipe is particularly suitable for energy conservation in hot and cold pipelines andplay an important role in maintaining constant temperature, protecting personal safety,preventing condensation and reducing noise. This product is rolled with a mold, closelymatched with the pipe, and the outer surace is polished to achieve precise insulation thickness.

Product Handling

Rock Wool pipes are lightweight and easy to handle. To cut the product, it only requires asharp knife with serrated edge or a hand saw, measuring tape and steel ruler. Rock Wool pipes should be secured in position using wire or metal bands in accordance with themanufacturer's recommendations and protected by metal cladding, mastic or othersuitable coatinas if required.

Product Specification

| Type | ROCKWOOL PIPE 80, ROCK WOOL PIPE 100, ROCK WOOL PIPE 120, ROCK WOOL PIPE 150 | |||||||||||

| Dia | Thickness (mm) | |||||||||||

| DN | INCH | ID | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 120 |

| 15 | 1/2 | 22 | ||||||||||

| 20 | 3/4 | 27 | ||||||||||

| 25 | 1 | 34 | ||||||||||

| 32 | 1-1/4 | 42 | ||||||||||

| 40 | 1-1/2 | 48 | ||||||||||

| 50 | 2 | 60 | ||||||||||

| 65 | 2-1/2 | 73 | ||||||||||

| 80 | 3 | 89 | ||||||||||

| 90 | 3-1/2 | 102 | ||||||||||

| 100 | 4 | 114 | ||||||||||

| 125 | 5 | 141 | ||||||||||

| 150 | 6 | 168 | ||||||||||

| 200 | 8 | 219 | ||||||||||

| 250 | 10 | 273 | ||||||||||

| 300 | 12 | 325 | ||||||||||

| 350 | 14 | 356 | ||||||||||

| 400 | 16 | 406 | ||||||||||

| 450 | 18 | 457 | ||||||||||

| 500 | 20 | 508 | ||||||||||

| 550 | 22 | 559 | ||||||||||

| 600 | 24 | 610 | ||||||||||

Specification | Specification | Specification | |||

Corresponding Inch (Approximate) | Pipe Ø | Corresponding Inch (Approximate) | Pipe Ø | Corresponding Inch (Approximate) | Pipe Ø |

1/2 inch (0.63) | 16 | 4 inches (4.25) | 108 | 13 inches (13.23) | 336 |

3/4 inch (0.75) | 19 | 4.5 inches | 114 | 14 inches (14.02) | 356 |

1 inch (0.87) | 22 | 5 inches (4.92) | 125 | 15 inches | 381 |

1 inch (1.1) | 28 | 5.5 inches (5.51) | 140 | 15 inches (15.35) | 390 |

1 1/4 inches (1.18) | 30 | 6 inches (6.26) | 159 | 16 inches | 406 |

1 1/4 inches (1.26) | 32 | 6.5 inches (6.65) | 169 | 17 inches (16.65) | 423 |

1 1/2 inches (1.38) | 35 | 7 inches (7.09) | 180 | 17 inches (17.01) | 432 |

1 1/2 inches (1.65) | 42 | 7.5 inches (7.64) | 194 | 18 inches (17.95) | 456 |

2 inches (1.89) | 48 | 8.5 inches (8.62) | 219 | 19 inches (19.02) | 483 |

2 inches (1.97) | 50 | 9 inches (9.02) | 229 | 20 inches | 508 |

2 inches (2.01) | 51 | 10 inches (9.65) | 245 | 21 inches (20.87) | 530 |

2.5 inches (2.36) | 60 | 10 inches (10.24) | 260 | 22 inches (22.05) | 560 |

2.5 inches (2.48) | 63 | 10.75 inches | 273 | 24 inches | 610 |

2.5 inches (2.48) | 63 | 11 inches (11.14) | 283 | 26 inches (25.98) | 660 |

3 inches | 76 | 12 inches | 305 | 28 inches (28.03) | 712 |

3.5 inches | 89 | 13 inches (12.8) | 325 | 30 inches | 762 |

4 inches | 102 | 13 inches (13.23) | 336 | 32 inches (32) | 813 |

Technical Data (ASTM C547)

| Item Name | Test Method | Standard Value | Test Value | |

| Dimension | ASTMC302-13(2017) | pass 0.034 0.044 0.062 0.073 0.099 650°C 4.54% 10.7% -0.4% 0.2% 0 0 pass 0.03kg/m2 | ||

| Thermal conductivity w/ (m-k) | 24°C | ASTMC335-17 ASTMC1045-19 | ≤0.036 | 0.034 |

| 93°C | ≤0.045 | 0.044 | ||

| 204°C | ≤0.065 | 0.062 | ||

| 260°C | ≤0.078 | 0.073 | ||

| 371°C | ≤0.111 | 0.099 | ||

| Service Temperature | ASTMC411-19 ASTMC417-15 | ≤650°C | 650°C | |

| Slag Resistance,max thickness change | ASTMC411-19 | ≤5.0% | 4.54% | |

| Non-Fibrous (Shot) content | ASTMC1335-12(2017) | ≤25% | 10.7% | |

| Linear Shrinkable at maximum use temperature( 650°C) | ASTMC356-17 | ≤2.0% | -0.4% | |

| Water Vapor Sorption By Weight | ASTMC1104/C1104M-13a | ≤5.0% | 0.2% | |

| Flame Spread Index | ASTME84-19a | ≤25 | 0 | |

| Smoke-developed Index | ≤50 | 0 | ||

| Stress Corrosion Performance | ASTMC795-08(2013) | No crack | pass | |

| Water Absorption | BS EN13472:2002 | 0.03kg/m2 | ||

- Excellent thermal insulation performance: Low thermal conductivity, effectively reducing heat loss and maintaining stable temperature.

- Non-combustible and fireproof: Class A non-combustible material, with high temperature resistance (thermal load contraction temperature ≥ 600℃), suitable for fireproof requirements.

- Good water resistance: Hydrophobic rate ≥ 98%, low moisture absorption, and not easy to be affected by humidity.

- High mechanical strength: Compression strength ≥ 40 kPa, with good dimensional stability and durability.

- Lightweight and easy to install: Convenient for construction and transportation, reducing installation costs.

- Environmentally friendly: Non-toxic, non-radioactive, and low in organic content (≤ 4.0%), in line with environmental protection standards.

- Wide temperature adaptability: Can withstand high temperatures up to over 1000℃ (melt temperature), suitable for various industrial and construction scenarios.

1. Industrial kilns, boiler linings, backing insulation, refractory steam engines,

2. Thermal insulation of thermal equipment such as gas engines

3. Flexible insulation materials for high-temperature pipelines; high-temperature gaskets; high-temperature filtration

4. Thermal insulation of thermal reactors

5. Fire protection of various industrial equipment, thermal insulation and fire protection of electrical components

6. Thermal insulation materials for incineration equipment

7. Raw materials for modules, folding blocks and veneer blocks

Engineered for superior performance, our quality Rock wool pipe provides exceptional thermal insulation for both hot and cold piping systems. Its precise, molded tubular design ensures a snug fit around pipes, effectively maintaining consistent temperatures, preventing heat loss, and controlling condensation. This reliable performance makes our quality Rock wool pipe an essential component for improving energy efficiency in industrial plants, commercial buildings, and marine applications, while also contributing to personnel safety by reducing surface temperatures.

The practical benefits of our quality Rock wool pipe extend to its ease of installation and handling. Lightweight and straightforward to work with, it can be quickly cut to size using common tools like a sharp knife or handsaw, significantly reducing labor time. Once in place, it is easily secured with wire or bands according to standard procedures. This combination of user-friendly installation and robust insulating properties makes our quality Rock wool pipe a smart, long-term solution for any project requiring dependable thermal management and condensation prevention.

PREVIOUS:

NEXT:

Rock wool pipe

CONTACT US

Classification

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!